Sherwood Ranger - Tube Fabrication - 11

*This web site is NOT owned or managed by G-TLAC. G-TLAC is not responsible for the content unless explicitly stated. See Disclaimer.

5/14/11 - page for tube ordering / cutting / drilling

5/17/11 - quote for tubes

Finally got tired of just passing by the parts in the garage, as there isn't a whole lot more to do with them, and what there is, I'm not all that excited about (large radius, but Z bend on the aileron bellcranks - how the heck to do that? and fishmouth the rudder pedal tubes - I don't really have the right tools for that, but I did one with just a unibit and some filing). So I got together a list of tube to buy and called Bralco in Phoenix, as recommended by a Sonex / CX-4 (and now maybe RV) builder that I've run into at Casa Grande a few times. Turns out Bralco doesn't sell tubes, but they refer you right over to Tube Service. So I download TS's pdf Al tube catalog and give them a call. Turns out they are divisions of the same overall company, so no wonder they hand off customers so easily. Spoke with Dan and emailed him a list of what I'm looking for. They only deal in 12-foot lengths, so the sizes that require less I may just end up mail-ordering via Spruce. I priced the whole collection at around $2200 from Spruce, so I'll see how Tube Service does. Though truck freight from Spruce for a 12-foot long pallet would probably add another couple hundred, with my cost to pick up from TS is just 2/3 tank of gas (about $30), so even if the price is a little higher, it could still be worth it. Then there's the satisfaction of not having to wait for a truck to arrive.

5/19/11 - quote for tubes, cont'd

Got the quote back from the tube company. Ok, so I'll wait a few days, but delivery from Phoenix is only $10, less than what I could drive up and back for. Price came back pretty good - about 15% less than ACS, even with state, county, and city taxes. Kind of scary, though, to be making a big purchase like this, because there's still parts of it I haven't figured out how to even get, much less build. Like the 1.5 x 1.5 x .065 for the firewall support beams doesn't seem to exist in 6061, so I'll use 1.5 x 1.5 x .125, but I'll have to figure out what else is impacted by that change.

5/20/11 - order tubes

Called back and let them know to go ahead with the order as quoted. So 118 lbs of Al is on the way. I let my wife, Carol, know that 118 lbs of Al would be arriving next Thursday morning, and her only question was - you're not planning on having to take off work for that, are you? Awesome support from the home front...

5/22/11 - tube planning

1/2 hr - filter spreadsheet on tubes, sort on diameter then length. Went back through what I ordered to check that it will actually fit in the number of lengths that will arrive, and to pre-plan the cuts to minimize left-overs, and to maximize the length uncut on the last piece of each diameter - to possibly provide a do-over on a part or two without having to re-order. Learned this strategy in working angle stock on the Sonex - if you pre-plan your cuts, you won't end up with four 10-inch scraps when the plans are calling for a 38" piece...

5/24/11 - Tube prep and planning

1/2 hr - clean off work table. 1/2 hr - cut and paste the plans sheets into one collection of parts requiring lathe / mill operations.

5/25/11 - Planning

1/2 hr - make spreadsheet of parts requiring lathe / mill operations.

5/26/11 - Tube planning

1/2 hr - Make additional worksheet within the parts list spreadsheet to lay out which parts are cut from which tubes to ensure that I don't end up with two foot-long scraps when I need a single two-foot length. Looks like everything plans out ok.

The truck from Tube Service. They said some neighborhoods are funny about a truck like this delivering. Looks pretty good to me. That's my stuff on the right side.

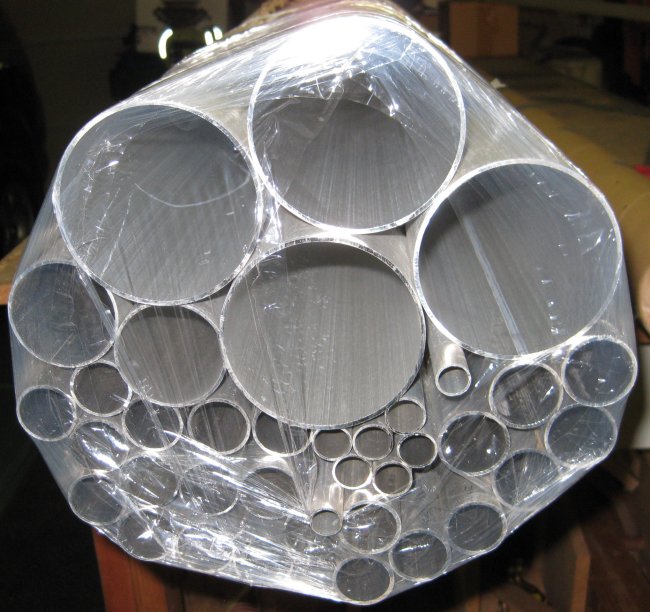

Evan with the big bunch of tubes. We'll see how big he is when there's an airplane rigged in the driveway... Much less going on a trailer to the airport...

Pretty well packed. There was another shipping tube with 3 lengths in it that they had to transfer from the Los Angeles warehouse.

The bundle on the table, plus the 20-foot length of rectangular tube. Don't need nearly that much of the rectangular, but paying more per foot + shipping from elsewhere, I decided to throw it in. This one came in a 24-foot shipping tube that I had to remove to get the garage door closed.

5/27/11 - unwrap tubes

That's a lot of tubes! Now to start making a bunch more short tubes from these long ones...

5/28/11 - rectangular tubes

1/2 hr - had to start with this one. The 20 foot length is just in the way, no matter where I put it. So broke out the miter saw, opened the garage door, backed the car out, and cut off 4 pieces (about 8 1/2 feet). So now the leftover fits in with the other tubes. Note to self - do this on less windy days. The clean-up was huge. These are the rails that support the seats.

5/29/11 - .625 tubes

1 hr - cut to length 4 of the 6 12-foot .625 tubes. Again, clean up is not insignificant, but a longer cutting session before the clean up is a more efficient way to do this. No particular reason to start with the .625's, other than they were easy to reach.

The miter saw setup.

Making a cut. Plywood behind to reduce chip spread.

Today's production.

5/31/11 - .625 and 1.0 x .036 tubes

1 hr - finished off the last 2 of the .625 tubes. Last one there's not much off of it, so maybe 8-9 feet / spare, so that went pretty quick. Did 5 of the 7 1.0 x .036 tubes. My little pre-planned cut list got all messed up on this one - got to the last segment on length #3 and there wasn't enough. So rearranged lengths #4, 5, and 6 - looks like plenty left in the 7th length in case something doesn't work out. Also, on length #6 of the .625 tubes, went to trim around 1" off the last piece. Did this the other day no problem, but today, the trimming was sucked in by the saw and mangled the tube. So for any that have less than a clampable length remaining, I'll just do those on the band saw.

1/2 hr - smooth all the tubes cut so far on the scotchbrite wheel. Still have to do the ID's, but the OD's go pretty fast.

6/2/11 - bandsaw blade, and a couple of 1.0 x .036 tubes

1/2 hr - installed the new bandsaw blade. Tried it out on 3 of the 1.0 tubes that needed short ends cutoff. Works really nice. After the disaster blade from the big box store, I should have done this sooner. Sprung for a nicer blade than I've ever had before - about $25. Very narrow cut, very smooth.

6/3/11 - 1 x .049 tubes, 1 x .036

1 hr - finished rough cuts on the last two lengths of .036. Got through all of the .049 - goes quicker since there are some longer parts here, fewer cuts to make. Still figure on about 2 hours to go with rough cuts.

Collection of tubes growing. Some of the longer ones aren't shown.

6/4/11 - 1 x .058, .065, 1.75 x .049 tubes

1 hr - got through the .058 and .065 tubes, plus the 1.75 x .049 (4 drag struts). Before cutting, went back through the .058 cut plan to leave the two that get bent to have as much extra length as possible. Will update the cut spreadsheet to note this. Stock remaining - the 1.125's and the 3" for the spars. There are still other tube sizes needed, but in much shorter lengths, so I'll get those from a short-order specialty company.

6/5/11 - tubes, all sizes

3/4 hr - ran a bunch of tubes over the Scotchbrite wheel to knock the external burr off. On a few, ran them axially into the wheel to smooth off the saw marks. Probably will go back and do the rest when I get to deburring the inside diameters. Made a few short cutoffs on the bandsaw. Also ran these on the belt/disk sander (disk side) to clean up the bandsaw cuts. Reorganized the work table to get all the tube shipping materials out of there, and to put the tubes remaining to be cut (1/2", 1 1/8", and 3") on the outer side.

Some of the tubes in a box to keep them together. There's a bunch of shorter ones in the bottom of the box that don't even make it into the photo.

Can almost see the bottom of the tube pile from here. Only the 3 sizes on the left remain to be cut. To the right of the wood blocks are the extra, and some of the longer keeper parts in between.

6/11/11 - tubes, 1.125, 3.0

1 hr - cut all of the 1.125 and the four main spar (3.0) tubes. Though I left several short 1.125 tubes for bandsaw slices because they are too short for the chop saw. This should end the need for the chop saw, at least for tube cutting.

6/26/11 - tube storage

1/2 hr - put some hooks in the garage wall, made up some loops of rope, and set the 3-inch tubes for the spars in the loops. Then stacked the extra lengths of the other sizes on these, leaving the work table open for tubes that are to become airplane parts. Gap in progress was due to getting the Sonex disassembled for paint, painted, and reassembled, plus a week out of town.

Hopefully safe, but at least out of the way stored on the wall.

Work table starting to clear - next up tube marking and drilling.

6/27/11 - debur 1.125 and sort tubes

1/2 hr - deburred the 1.125 tubes. Sorted tubes into wing / tail / fuselage / gear / other categories. Noted that I had left several 1.125's that were too short for the chop saw.

6/28/11 - move tubes and cut 1.125

1/2 hr - moved the wing tubes over to the others hanging on the wall. There's 4 aileron spars, 4 interplane strut tubes, 2 smaller diameter that are the rod between the ailerons, and 4 shorter ones that may be braces for the interplane struts. There also should be some others that are the aileron bellcrank supports. Also put a couple of the longer tail tubes over there - the leading edges for the elevators, and the wing drag struts. Put the tail-specific and landing gear tubes on shelves on the other wall. That leaves the fuselage tubes, which all but four fit in a box (well, hanging out diagonally). The longest four are the longerons in the tail - about 8 1/2 feet for the longest pair. Then cut the remainder of the 1.125 short tubes (12 pieces). Other than one of the smaller diameter tubes to be cut in half for the elevator trailing edges, I've cut all of the sizes that I have. So now most likely will have to start figuring out how to mark and drill what I've got, and place an order for the sub 12-foot sizes that are still needed.

All the fuselage tubes except the four longerons. There's a bunch of shorter tubes in the bottom of the box that don't show - box weighs about 40 lbs.

Not very exciting - the short 1.125 tubes I cut on the band saw.

Click to join sherwoodbuilders