Sherwood Ranger - Tube Fabrication - 11A

*This web site is NOT owned or managed by G-TLAC. G-TLAC is not responsible for the content unless explicitly stated. See Disclaimer.

7/2/11 - Second tube work page

Decided one page for tube work was getting too long, so split it here. Decided work in the garage is hopeless at this time of year, with temps over 115F in the shade. So since marking hole patterns on tubes is one next logical activity, decided to see if I could clear out the office in the house enough to bring in the crate of tubes for hole location marking. After about an hour of rearranging, it's looking promising.

7/3/11 - Tube marking

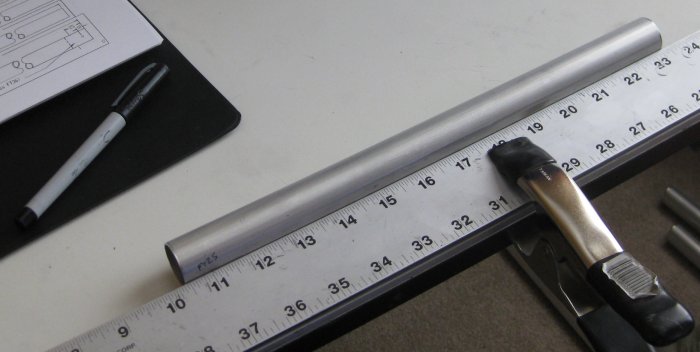

1 1/2 hr - Moved the old drafting table into the office, as well as a box of tubes. On the edge of the table, spring-clamped a length of .250 thick stock and one measuring stick. This was a good thickness for marking a line down the .625 dia. tubes. Did all those (not the whole length, just at each end where the holes will go). Then added another measuring stick to the stack and did most of the 1" and 1.125" dia. tubes.

View of the setup for marking both ends of a tube so the holes are clocked the same.

Another view of tube marking setup.

7/7/11 - Tube marking

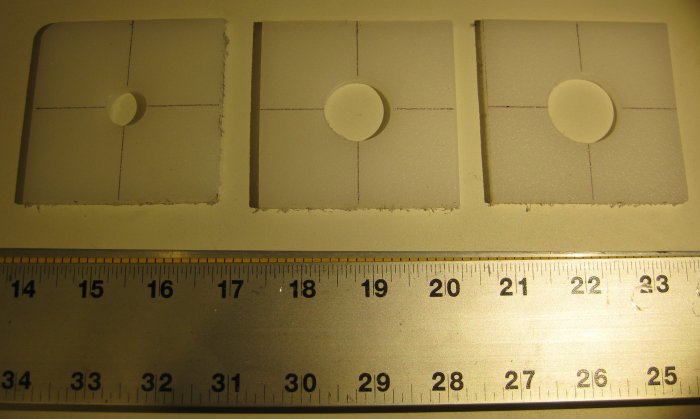

1/2 hr - made up .625, 1.0, 1.125 tube marking tools. Saw this in a welding book and made them from an inexpensive kitchen cutting board. Using (3 different) unibits to step up to the hole size, they fit snug on the tubes. Mark the plate with perpendicular lines first, then drill hole at intersection point.

0.625", 1.0", 1.125" 90-degree marking tools.

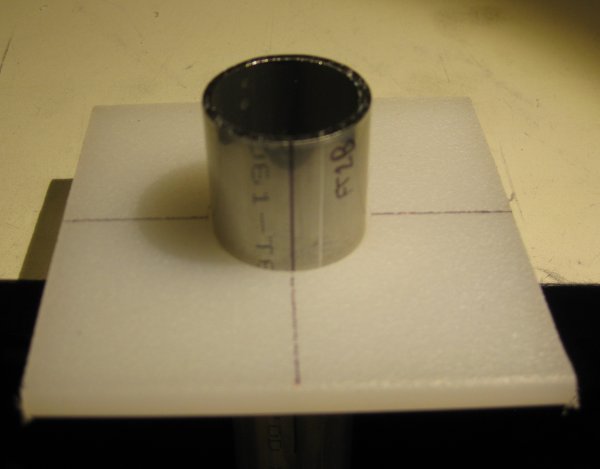

Tool in position on a tube.

7/7/11 - Tube marking

1 hr - started marking some tubes. This is where things slow down. 11 tubes marked, including one that gets no holes. So that's ~10 tubes / hour. I don't even know how many tubes I have sitting here. Maybe I'll get faster at it - and a bunch of them have the same hole pattern, so less time looking for and checking dimensions.

7/8/11 - Tube marking

1.5 hr - marked 14 more tubes.

7/10/11 - Tube marking

1 3/4 hr - marked 41 more tubes, though there was at least 1, and maybe 2 that were extras cut in error.

7/13/11 - Tube marking

1 1/2 hr - marked 29 of the .625 tubes, and identified 2 that are to be drilled at assembly. Did these more assembly-line style - mark all 180 degree marks using the marking tool. Then extend all 180 degree marks up the tubes. Then measure and mark all hole locations along the tube. Also probably helped that all of these have the same hole pattern.

7/15/11 - Tube marking

3/4 hr - marked 13 more tubes.

7/16/11 - Tube marking

1/4 hr - marked 2 more tubes. That's it, for the initial fuselage/tail batch, except for maybe a dozen really short doubler (sleeve) tubes, and the 4 tail longerons. Brought the 4 tail longerons inside, but not sure I can mark them in the room where I did the rest. Also need to smooth off the short tubes, as I cut those on the bandsaw. Found a ~$50 lathe on Grizzlyindustrial which may be possible to use to put the chamfered ends on the several tubes that call for that feature. 8.75hr so far in marking tubes for drilling - about 2x quicker than I was projecting based on the first few that I did.

1/4 hr - marked one of the lower longeron tubes. Not so bad - just a long straight line, then keep inspecting the plans until I saw all 13 holes. Seemed like 12 for a while, but 13 are defined. Then flip them around the tube until it looks like the print.

7/18/11 - Tube marking

1/4 hr - marked the other lower longeron tube. Again, which side of the tube the holes are on is confusing, mostly because I put the first longeron next to the 2nd to try and make a mirror of it, but I had so many mistaken marks on the first one I still got it confused.

7/19/11 - Tube marking

1/4 hr - marked the first upper longeron tube. 7/20/11 - Tube marking

1/4 hr - marked the second upper longeron tube. Longerons marked!

7/21/11 - Tube drilling practice

1/2 hr - marked up a sample tube (cutoff scrap). Tried out the center finder. Seems to be pretty easy to get the vise centered correctly on the drill press to hit the center of the tube. Then tried the center drill on a few holes. A bit slow to get the holes lined up, but at least with the center drill there is no wandering of the bit - it just goes right into the tube.

Center finder and center drill.

Center finder from Grizzly Industrial, item H2940, $3.50.

Center drill - drilling tip is 5/64" (number 2 in center drill sizes). Shank is 3/16".

7/26/11 - Drill tubes

1/2 hr - practice is over. Time to drill some real tubes. Got 3 done. Ok, so this is going to take a while. Though I find once the clamp centerline is set, it stays set, so the time is in lining up each individual hole, and the clamp only has to be reset when the diameter changes. So will stick with all 1.0" diameter for now.

7/28/11 - Drill tubes

1/4 hr - drill 3 more tubes. This is going to take a while...

7/29/11 - Drill tubes

1/4 hr - drill 2 more tubes.

7/30/11 - Drill tubes

1/2 hr - drill 6 or 7 more tubes.

1/2 hr - drill 6 or 7 more tubes. Found one that is drill at assembly (no holes yet).

7/31/11 - Drill tubes

1/4 hr - drill a couple more.

1/4 hr - drill a couple more. Feel my enthusiasm. Probably could crank this all out in a good solid couple of hours...

8/1/11 - Drill tubes

1/2 hr - drill ~7 more tubes or so. Seem to be about 2/3 of the way through the 1.0 dia.

8/2/11 - Drill tubes

1/2 hr - drill a few more tubes. 1.0 dia down to about 7 tubes remaining...

8/3/11 - Drill tubes

3/4 hr - Finished off the 1.0 dia tubes (57 total). Re-set for the 1.125 tubes and drilled the first one of those. Just about 4 hours for all 57 of the 1.0 tubes (except for the 4 longerons - haven't done those yet). Not bad.

May not look like much, but that's stacked 3 deep.

Ah, tubes with holes in the ends, just like the plans show...

Tube in vise on drill press.

Check alignment before drilling.

This isn't that complicated. Get the vise lined up with the center finder once per diameter, then all the tubes of that diameter will be square to the drill.

Deburring inside the ends. I thought this might involve a lot of time with round files, but the swivel debur is just right for this.

8/5/11 - Drill tubes

1/4 hr - drilled a couple more 1.125 tubes.

8/6/11 - Drill tubes

1/4 hr - drilled a couple more 1.125 tubes.

8/7/11, 8/8/11, 8/9/11 - Drill tubes

3/4 hr total - finished the 1.125 tubes. Re-set up for the .625 tubes, drilled the first one of those. So roughly 1 1/4 hr total for the 1.125 tubes.

8/10, 8/11/11 - Drill tubes

1/2 hr total - drilling .625 tubes. These go much faster - all the same hole pattern, and only 4 holes per tube. Just under halfway done.

8/12/11 - Drill tubes

3/4 hr - finish drilling the .625 tubes.

8/13/11 - Debur tubes

1/2 hr - using the swivel debur, deburred inside the ends of all the fuselage/tail tubes drilled above.

1.125 and .625 tubes drilled and ends deburred.

This view maybe gives an idea of how many .625 tubes are in there, though perhaps half of them still are not visible through the end of the box.

The longer 1.0 diameter tubes.

The shorter 1.0 diameter tubes.

Click to join sherwoodbuilders