Sherwood Ranger - Tube Fabrication - 11C

*This web site is NOT owned or managed by G-TLAC. G-TLAC is not responsible for the content unless explicitly stated. See Disclaimer.

Split into yet another tube-specific page, to separate the odd-size tubes ordered separately from the big order...

9/19/11 - Small order of tubes arrives.

The shipping tube from onlinemetals. 75" long x 6.5" dia.

Tubes loosely rattling around inside - not so cool. Though their end cap system is very difficult to dislodge, so even though there were several pounds of tubes rattling from end to end, it takes a LOT to get the ends off. Though I don't see why they couldn't invest in a little plastic wrap to keep everything together. If an end cap did come off, that would be it - some of the order would inevitably be lost.

The tube order - 13 pieces.

9/19/11 - Cut a few.

1/4 hr - cut 1.125 x .125w (2 pcs) and 1.5 x .063w (1 pc). That's all there is of these sizes.

10/2/11 - More tubes.

1/2 hr - cut 4 pcs from the 1.0 x .125w. Cut to length the 1.75 x .058w for the control column.

3/4 hr - cut 2 pcs of 1.75 (landing gear) and 4 pcs of 1.125 x .058 (wings) using the chop saw. Most of the time there is clean-up.

That's all there is for the cut-to-length that don't require a lathe to adjust to a different od.

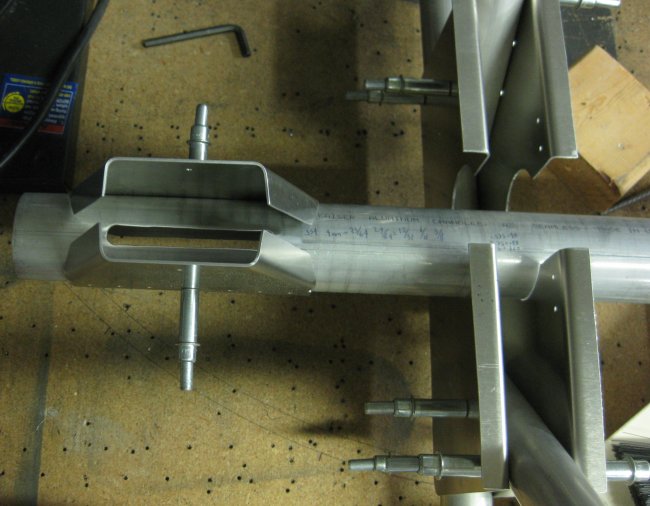

1 1/2 hr - marked, drilled, and slotted the control stick torque tube. Figured I may as well get this out of the way.

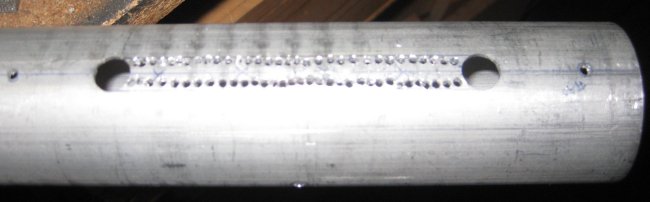

Drill a series of small holes near perimeter of the intended slot.

Cut through between the holes with a cutoff wheel in a Dremel tool.

File the slot smooth. This is in the fuselage frame, with the control stick support brackets clecoed on.

Click to join sherwoodbuilders