Sherwood Ranger - Machining - 13

*This web site is NOT owned or managed by G-TLAC. G-TLAC is not responsible for the content unless explicitly stated. See Disclaimer.

Page for fabrication of parts requiring a lathe or milling operations.

12/10/11 - Tube inserts

1 hr - took some lengths of tube to Adam B., who I met through the local EAA chapter. He's got a pretty good-sized lathe and a Bridgeport in his garage (among welding and powder-coating equipment). He's going to work on some of the tube insert type parts. After that, we'll see if he would be willing to continue with some of the other parts. I brought him a powerpoint file with all of the mill/lathe parts to see what all is in this project, as well as a list from my excel parts list file of what all the inserts are - OD's required + what tubes they go into. Also brought tube samples for fit checks.

12/18/11 - Tube inserts

1 1/2 hr - went over to Adam's place. We got a couple of parts made. He drove the Bridgeport. I confirmed some of the metric conversion and made some decisions with respect to some of the dimensions based on knowing what the parts are used for and where they go. Nice looking part. Too bad they end up buried inside some tubes, but they should work great.

1/17/12 - Tube inserts

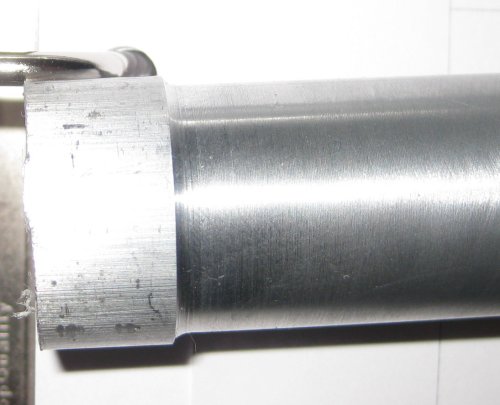

2 hr - at Adam's place. Got several segments of tube turned down to become tube inserts. These are the inserts to go into the 1 x .065 and the 1 x .058 tubes.

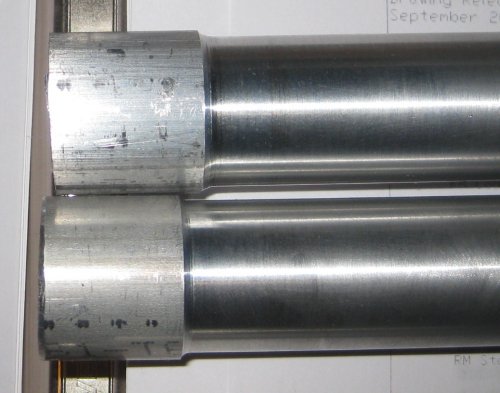

The turned area on each of these is 9 - 10" long. Top one is turned from 1.0 for the .058 tubes. Bottom three are turned from .875 for the .065 tubes.

1/18/12 - Tube inserts

1/4 hr - mark the above turned tube stock for cutting.

1/19/12 - Tube inserts

1/4 hr - cut the tube stock on the band saw.

1/4 hr - sanded / scotchbrited a couple of the parts.

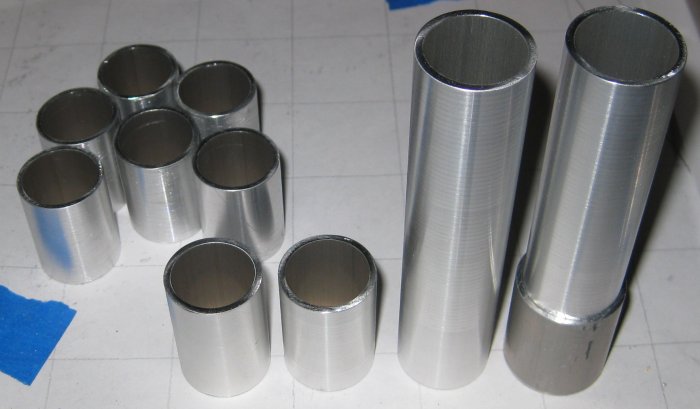

Some of the inserts.

1/20/12 - Tube inserts

1/2 hr - finished sand/scotchbrite of the parts. Located some of the tubes the inserts go into. Smoothed the pilot holes inside the tubes with a file and got a couple of the inserts into one of the tubes. Very nice fit.

Some more of the inserts.

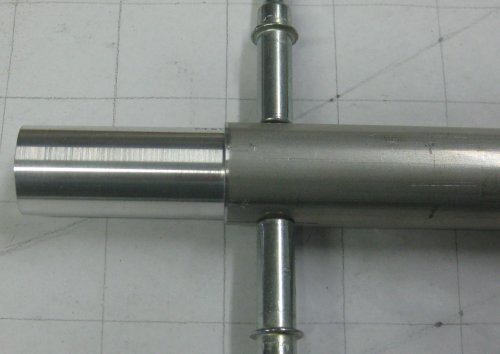

Was trying to get a low enough angle to see the end of the insert inside the tube, but anyway, very nice fit.

1/21/12 - 1/23/12 - Tube inserts

1/2 hr - got most all of the inserts fitted into the tubes. Couple more to go, then I will start drilling the inserts through the pilot holes in the tubes.

1/24/12 - Tube inserts

3/4 hr - drilled the inserts to the tubes. Drilled the rivet holes to final size. Deburred a couple and pulled a couple of 3/16 rivets - no way to pop those by hand - had to step on the hand-puller handles for those. I hope the pneumatic puller can pop these, or I will have to get a hand puller with more leverage...

1/25/12 - Tube inserts

1/2 hr - Marked and drilled the final 2 inserts into the associated tube. Pulled a couple more rivets - need to get the pneumatic going - hand pulling 3/16 doesn't go very well, at least not with this small hand puller.

Fuselage Tube no. 50 - forward h-stab attach points.

Long inserts - protrude farther inside and stick out farther outside than any other tube inserts.

1/26/12 - Rivet puller

1/2 hr - worked on getting the rivet puller going. Tried to pull a couple of sample rivets in scraps first. Good idea - that puller isn't really up for the task. First couple of pulls, it drew the stem into the rivet body, and just barely broke the stem on a 2nd pull. Then I tried it on a part, and it just got stuck. Perhaps these are really only rated for 3/16 rivets if they are all-aluminum. These SST ones are a good bit tougher to pull, but probably still a lot less impact into the part than using a rivet gun to drive Al rivets of similar size...

1/27/12 - Rivet puller

1/2 hr - stopped by HF and got the larger capacity (1/4") puller. Got that connected up. THIS is what is needed to pull those 3/16" rivets. Pulled them no problem. Finished pulling about 2 dozen rivets to complete the remaining inserts that I have at this point.

Rivet looks pretty big on that 1" tube.

1/27/12 - Tubes for inserts

1/2 hr - went through the list of tubes needing inserts and pulled them from the boxes of tubes. The boxes at this point are more or less sorted into - forward of the forward frame, between the two frames, and aft of the aft frame (forward/mid/aft fuselage, in the 1" dia. tube area).

1/28/12 - Tubes for inserts

1/2 hr - filed the insides of the tubes where the inserts go. This is to clean off the burr from the pilot holes, which is necessary to allow the inserts to slide in. Pretty much ready for more inserts, at this point.

2/16/12 - Insert stock

2 hr - after a week off for visitors from out of town, then another weekend for the FIRC (Flight Instructor Refresher Clinic), finally got back to working on some parts. Got over to Adam's place and got some more tube insert stock turned. Also discussed how to make the 3 deg. and 6 deg. wedge plates - turns out the stock I had started on the belt sander is not usable. Still have another diameter of tube inserts to go (about 20"), but this will take a while to get turned into inserts and stuck into tubes.

Today's accomplishment. This is insert stock for .036 wall tubes.

For the finish cut, he used 144 turns / inch of feed for a very smooth finish.

Then went over it with some 1500 grit while still on the lathe.

2/17/12 - Mark inserts

1/4 hr - marked the insert stock for cutting.

2/18/12 - Cut inserts

3/4 hr - cut the 20 inserts from this size of stock. Sanded/Scotchbrited/deburred 6 of the 20 and inserted them into 6 single-end-only tubes. Some of the tubes get inserts in a single end because the other end is joined by multiple rivets or the like rather than a single bolt.

20 inserts cut and lining them up with the tubes they go into.

6 inserted into single-end tubes. Brings wall thickness up to .125.

The unusable cutoffs. Might have been just a hair more efficient, but at $6/foot, these throwaways don't seem excessive to me - might have squeezed another $0.50 out of it...

2/18/12 - more insert work

1/2 hr - drilled 6 inserts to the tubes. Sanded/scotchbrited/deburred 4 more inserts. Drilled those to the tubes. Started sanding the remaining 10 inserts.

2/19/12 - inserts

1/4 hr - finished sanding/Scotchbriting/deburring the remaining 10 inserts and put them into the tubes they go with. At this point, 3 inserts stay loose because the far-end holes in the tubes are drilled at assembly to allow for alignment.

1/2 hr - drilled the inserts to #40 and started up-drilling the rivet holes to #30.

2/20/12 - inserts

1/4 hr - finished drilling to #30 and to #21. Final size will be #12.

2/21/12 - inserts

1/2 hr - drilled to #12, deburred the outsides, cleaned the hole location marks off the tubes.

2/22/12 - inserts

1/4 hr - deburred the insides of the tubes and pulled the rivets. Removed the clecoes.

2/24/12 - angled plates / saddles

1/2 hr - marked out and cut blanks to use for machining the angled plates (.125 and .062 thick). Also cut 13/16" wide strips from the .250 bar. These will be milled to .750 wide and have .5 radius ball-end cut of various depths to make the saddles for 1.0 tubes.

2/27/12 - tube clean-up

1/2 hr - cleaned off the extraneous markings from the tubes that had inserts riveted in. These mostly consist of the lines marked on the tubes to indicate the 90 degree increments for the hole locations, but also tube numbers. Replaced the tube numbers with numbers marked on masking tape for easy removal later. Need all markings off the tubes since the solvents for the covering system (if I go with an MEK-thinned covering system) will cause any remaining ink to bleed into the covering system - and since each layer is also MEK-thinned, ink can bleed through the final color coats.

2/28 & 2/29 - tube clean-up

1/2 hr (total) - continued removing markings from tubes.

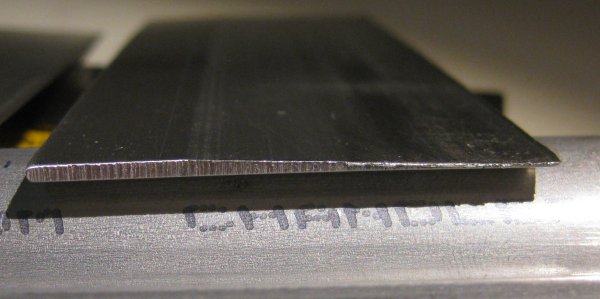

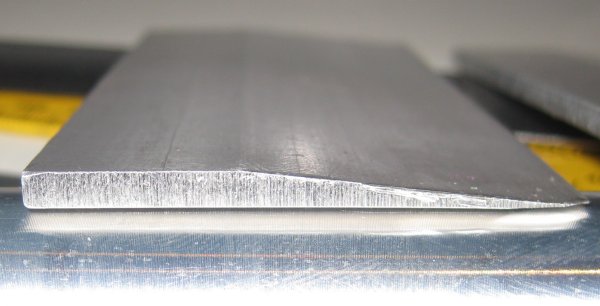

3/10/12 - angled plates

3 hr - at Adam's place. Got 3 of 4 angled plates cut (wedge plate/spacers). 4th one, the mill grabbed it. Also turned the insert stock for the .049 tubes.

The day's product.

Trying to show a 3-degree slice.

The 6-degree slice.

Click to join sherwoodbuilders