Sherwood Ranger - Making Parts - 3

*This web site is NOT owned or managed by G-TLAC. G-TLAC is not responsible for the content unless explicitly stated. See Disclaimer.

12/23/10 - .063 parts

1 hr - had a little time so cut 12 more parts from the .063 sheet. These are the little shield-looking plates. I believe these form part of the aileron hinge. Got 5 of them through sanding and scotchbriting.

12/24/10 - .063 parts

1/2 hr - finished off the balance of sanding and scotchbriting the plates. Also sanded/scotchbrited a few other .063 parts - rectangles.

12/24/10 - .063 parts

2 hr - had a nice solid block of running the bandsaw. Finished cutting out the .063 parts. At the end, tried trimming a few of the .125 parts with this new blade. Slower, but still good control. I think I'll make it through. .040 and .050 should be even easier.

2 hours - 38 parts, not bad. I count 74 .063 parts total. Now it's onto sanding, scotchbriting, marking, and drilling (and a few bends).

Christmas present - an oscillating sander for those inside curves.

Curves like on this part. There's a bunch of these in the .125 parts, and it might also make the various saddle-type parts.

12/27/10 - .063 parts

1/2 hr - drilled about a dozen of the .063 parts. These are plates in the ailerons, as such they have a 1" dia. hole - I need to check how tight that 1" is - if it's just clearance for the spar, or if it supposed to be snug to it.

12/28/10 - .040-.050 parts

1/2 hr - made a few cardboard patterns for a couple of the .040 and .050 parts.

12/29/10 - .040-.050 parts

2 hr - made more cardboard patterns for the .040 and .050 parts.

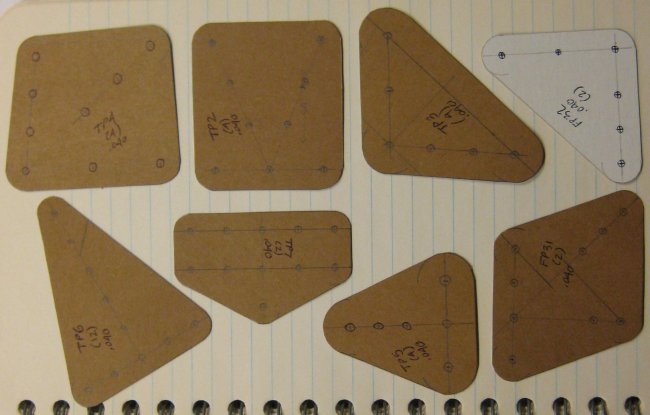

The cardboard patterns for the .040 parts that are not rectangles.

The cardboard patterns for the .050 parts that are not rectangles.

12/29/10 - .050 parts

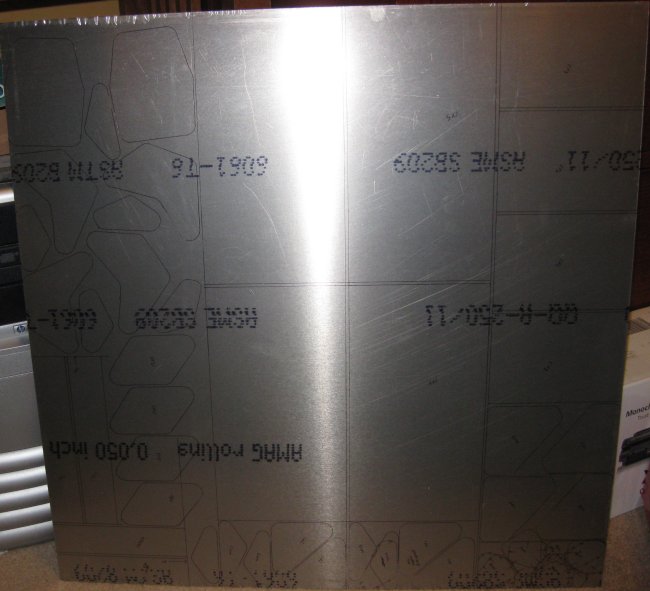

2 hr - laid out all of the .050 parts on 2'x2' sheets.

These 2x2 sheets look all scratched. They are not. There is a peel-off plastic coating on both sides, so I have been marking them, cutting them, then peeling off the coating when they get to the edge-smoothing step.

Almost the entire bottom half of this sheet is extra - pretty close to my rough hand-sketched planning layouts. I count 70 total .050 parts.

12/30/10 - .040 parts

1/2 hr - laid out all of the .040 part on one 2'x2' sheet.

All of the .040 parts fit on one 2'x2'. Don't count what's on here - I drew a few extra to decide later what is easier to cut.

General note on cardboard patterns - I used 17 for the .250, .188, .125 thicknesses, with two 1-off .250 parts just laid out directly on the metal. I used 13 for the .063 parts, 8 for the .040 parts, and 10 for the .050 parts. So that's 48 patterns for all of these parts. With these patterns and includng rectangles / squares / trapezoid shapes, so far I have laid out 245 parts. I know there's a few more simple squares/rectangles for saddles (about 24 of these), so given that I've counted about 915 metal parts total in the airplane, this really seems to be moving along. I have yet to add the wood parts, mostly in the wings, to the spreadsheet.

Click to join sherwoodbuilders