Sherwood Ranger - Making Parts - 4

*This web site is NOT owned or managed by G-TLAC. G-TLAC is not responsible for the content unless explicitly stated. See Disclaimer.

1/3/11 - .063 parts

1/2 hr - sanded and scotchbrited 6 more parts.

1/4/11 - .063 parts

1/2 hr - marked and drilled 4 parts.

1/5/11 - .063 parts

1/2 hr - peel plastic coating off the remainder of the .063 parts.

1/6/11 - .063 parts

1/2 hr - sanded and scotchbrited 16 more parts.

1/7/11 - .063 and .125 parts

1/2 hr - sanded and scotchbrited 7 more parts, and started sanding on 19 more. Didn't finish these, as I was running them until they got hot and then put them back on the table to cool off, and this was as far as I got before my fingers were tired of the heat and vibration.

1/8/11 - .040 parts

3/4 hr - ran the bandsaw and got through cutting out about half of the .040 parts.

1/2 hr - sanded and scotchbrited a bunch of these parts. .040 cleans up fast.

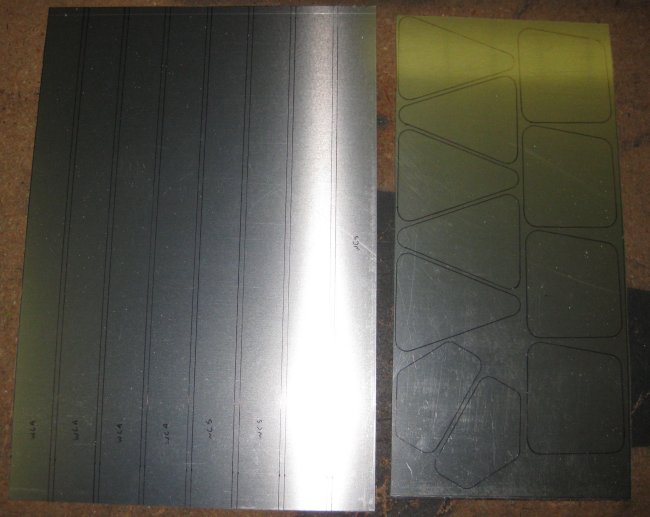

The parts cut out. The large rectangles are blanks for the forward foot boards.

What's left to cut from the .040.

1/9/11 - .040 parts

1/2 hr - sanded and scotchbrited some more parts. About need to run the bandsaw some more - only a few left to sand.

1/11/11 - .040, .063, .125 parts

3/4 hr - sanded and scotchbrited a bunch more parts.

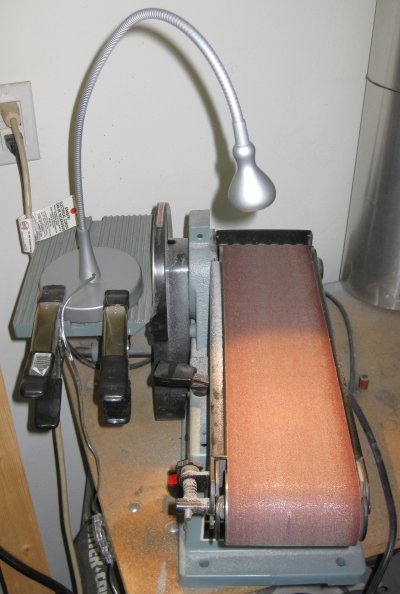

Was up to Glendale for the big game, so on the way back, we stopped at Ikea. I got a Jansjo light to use as a work light in the garage, to replace a very old, taped-together, very hot halogen desk lamp I had been using. The Jansjo sits on the belt sander with a few spring clamps and is a cool LED, for only $10.

1/12/11 - .040 parts

1/4 hr - drilled some small gussets.

1/13/11 - .040, .063, .125 parts

1/2 hr - marked and drilled a bunch of parts to use as pattern parts for drilling the rest later.

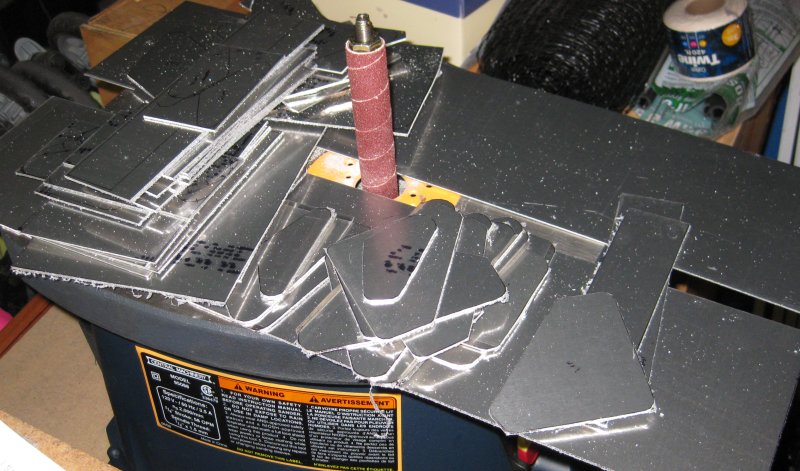

The next part of the process - adding holes.

.040 parts.

1/14/11 - .040, .063 parts

1 hr - used the pattern parts to drill the multiple copies of some of the parts. Deburred a bunch of the drilled-through parts, and sorted the parts drawer into ready-for-build vs. parts that still need more drilling or edge smoothing, because there is starting to be enough of them that it's getting confusing, and no point wasting time stacking and re-stacking parts that are ready just to find some that are not quite done.

1/15/11 - .063 parts

1/2 hr - more drilling using pre-marked parts as patterns.

The done box. Doesn't look very impressive at this point, but there's a lot of stuff that is in process, and only a few minutes per part will finish them off.

1/17/11 - .063 parts

1/2 hr - more drilling. Tried some that have 1 inch dia. holes through. Got a step drill from Harbor Freight on the way home from work. Seemed to go ok, but I think the platform on the drill was leaning, causing the holes to walk away from the starting location a little. The platform is built-up with a stack of scrap wood blocks to give something for the step drill to sink into. I will need to re-stack that stuff to see if I can get it more square.

1/20/11 - .050 parts

1 3/4 hr - started by finishing off a few .040 parts, then the rest of the time taking the .050 2'x2' squares down to size. The blade walked off the bandsaw drive wheels after a while, so I adjusted the tracking by turning a screw that angles the axle of the top wheel in the saw. MUCH better. It holds tight to the guide blocks and bearings now. The pile of .050 parts looks surprisingly small after being cut from 2 1/2 of the 2'x2' squares. There's still a few more to finish off, but I got through well more than half of the cutting.

This is it, plus two larger rectangles that form the aft foot rests.

1/23/11 - .040, .125 parts

1/2 hr - processed a few more parts through sanding and scotchbrite-wheeling.

1/24/11 - .040, .050 parts

1/2 hr - marked and drilled a few more parts.

1/26/11 - .050 parts

1/2 hr - drilled a few more parts.

Click to join sherwoodbuilders