Sonex* Forward Fuselage 6

*This web site is NOT owned or managed by Sonex, Ltd.. Sonex, Ltd. is not responsible for the content unless explicitly stated. See Disclaimer.

Work goes slower when the garage is cold (30F in this picture). 12/18/99.

No, it's not a coffee table. The cups are full of clecoes. The shelves in the sawhorses are great for keeping tools off the floor. 12/18/99

All the parts were drilled, returned to basement for deburring, and brought back to the garage. Brought the car in after work and opened the hood. Engine heat + an electric heater kept the garage above freezing long enough to get a lot of rivets and bolts installed. Rope is to keep airplane from falling off sawhorse. I had it in the spar box when the fuselage was inverted, but of course I didn't put it back until the tail cone fell on me when I did the aft fairleads. Fortunately the tail cone alone is not very heavy. (No bottom skins on plane - it is supported at sides only, so it doesn't take much to move it off the sawhorse.) 12/21/99

Got the tail fastened on, plus the firewall & forward spar box. 12/21/99

Used a regular rivet in the lower outer corner of the forward spar box - should not interfere with the spar, and I could not get the countersink into that corner anyway. 12/21/99

The aft cockpit structure. Parts just set in place. Similar to the tail, I will clamp these in position, trace around the perimeter of the parts, remove the parts, lay out the hole pattern within the traced lines, drill pilot holes in the cockpit bottom skin, clamp the parts back into position, then drill up through the bottom skin. With this process, holes are quite likely to be in the right position. 12/22/99

Finally have enough to sit "in"! Seated in the center. Center solo is the way to go - plenty of space and a great view. 12/26/99

Seated on the left side. There was another inch or two to move over, but elbow room in the center is tight. (I'm 6'-1", and wearing 6 layers of clothes!) Tomorrow marks exactly 5 months' work on the Sonex - somewhere around 425 hours (that includes the complete tail, all the wing ribs & the fuselage). 12/26/99

Clecoes in rotation. 12/27/99

Bottom skin all clecoed. 12/27/99

Frames clamped and drilled. 12/27/99

Drilled seatbelt brackets to 5/16, then I riveted the frames outside of the fuselage. Would be very difficult to rivet these in place. 12/27/99

When installing -4 rivets in idler assembly, they would not all fit, so I used some -2's. Another possibility would be to offset the holes in the brackets so the rivets are not opposite each other. 12/27/99

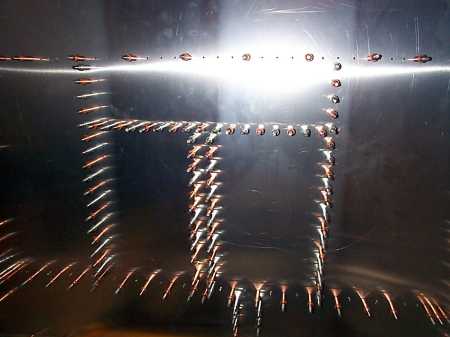

Bottom all riveted. 12/27/99

Seat in place. 12/27/99

Idler installed behind seat. 12/27/99